Project relevance

The main goal of this project is the construction of production facilities for the storage, transshipment and processing of grains and oilseeds, which will help to unload and eliminate the logistical collapse resulting from the war. Among the long-term plans for the work of the enterprise is the creation of a whole complex of processing enterprises on the basis of the elevator, as well as a dry port (hub for transshipment of goods using containers) that will increase the export potential of Ukraine on the western border.

Assets

Land plot - 13 hectares (lease agreement for 49 years, there is a plan to buy the land plot)

Location advantages:

- Territorial location near the border with the European Union.

- Possibility to reload products on the railway tracks of the European standard (documents have been submitted for obtaining technical specifications to Ukrzaliznytsia for joining the narrow and wide railway line passing along the site)

- A large area of land for promising development by grain processing enterprises.

- Ideally suited for the creation of a logistics center for shipment by road, rail, container transportation.

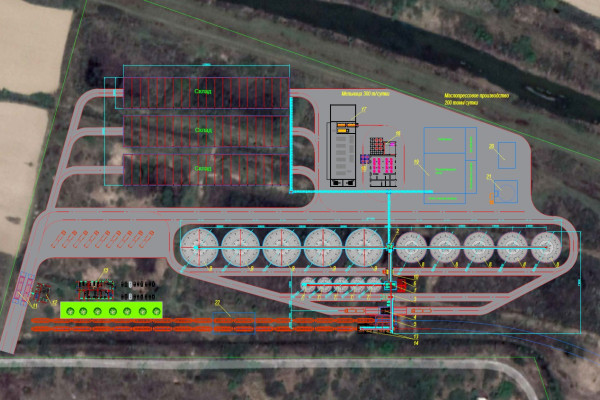

- Elevator complex project

The layout solutions and the technological scheme of the elevator project provide for the following technical and economic indicators of the facility:

- Reception of products from vehicles - 1,000 tons / day.

- Reception of products from railway transport - up to 4,000 tons / day.

- Primary cleaning of products to commercial quality indicators - 4,000 tons / day.

- Removing excess moisture from products - 500 tons / day when calculating for corn when removing 10% moisture.

- Storage of products up to 100,000 tons.

- Shipment of products to vehicles - 1,500 tons / day.

- Shipment of products to railway transport - 4,000 tons / day.

- The annual turnover of products at the elevator is more than 1 million tons.

Storage of products is carried out in metal silos with a volume of:

- 12 476 cubic meters - 5 pcs.

- 8 442 cubic meters - 5 pcs.

- 1 261 cubic meters - 5 pcs.

The next stages of the development of the site provide for the organization of the following production facilities:

- Flour-grinding production, with a capacity of 300 tons / day for incoming products.

- Oil press production, with a capacity of 200 tons / day for incoming products. The production waste of this enterprise will be sunflower husk, from which the production of pellets will be organized, which in the future will be used, incl. as fuel for the dryer of the elevator complex.

- Cereal factory, production of pasta

- Plant for the production of halva (relocation of existing facilities to the territory of the complex according to an existing agreement).

- Corn processing plant

- Industrial refrigeration complex for storing vegetables, fruits, meat, fish.

- Dry port with subsequent shipment of containers to the port of Rijeka

- To supply the production facilities with energy, power lines will be connected to the territory and a transformer substation with a capacity of 1.5 MW will be equipped at the first stage with its subsequent increase to 3 MW.

Budget of the project

|

Investment directions |

Investments amount, $ |

|

I STAGE |

|

|

Design work |

75 692 |

|

Elevator construction and building materials |

2 242 607 |

|

The cost of technological equipment |

2 138 736 |

|

Installation of technological equipment |

335 152 |

|

Automation and electricity |

402 093 |

|

Construction of 2 railway lines |

1 154 625 |

|

Project management |

145 172 |

|

TOTAL FOR THE 1st STAGE (including VAT) |

6 494 077 |

|

II STAGE |

|

|

Elevator construction and building materials |

2 772 712 |

|

The cost of technological equipment |

6 101 456 |

|

Installation of technological equipment |

769 105 |

|

Automation and electricity |

502 365 |

|

Project management |

119 852 |

|

TOTAL FOR PHASE II (including VAT) |

10 265 490 |

|

TOTAL (including VAT) |

16 759 567 |

Indicators of economic efficiency of the project:

- Project horizon: 60 months

- Construction period: 11 months

- Need for borrowed funds: $16,900,000

- Project investment costs: $16,759,567

- Payback period: PBP 48 months.

- Discount rate: 3%

- Discounted payback period: DPBP 50 months.

- Net present income for 60 months. project, NPV $7,187,396

- Discounted net present value for 60 months. project, DNPV $5,359,841

- Average rate of return, ARR 28.58%

- Internal rate of return, IRR 15.14%

- Modified internal rate of return, MIRR 8.52%

- Profitability index, PI 1.43

Additional information is available upon request.