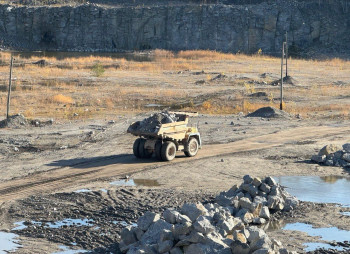

The field covers 54.9 hectares. The area of the leased territory is 88.09 hectares (7 sites). The mining allotment of the block stone extraction site is 15.92 hectares, and the crushed stone extraction site is 33.28 hectares. The land lease agreements are valid until 2036.

Special mining permit until 2036. The permit includes two separate areas: for the extraction of block stone (Cardinal Grey GG4) and rubble stone for the production of crushed stone.

The balance reserves as of 2024 amount to 15.762 million m3, including 3.176 million m3 for blocks (categories A + B) and 12.586 million m3 for crushed stone (categories A + B + C1).

In addition, in the C1 category, the conditional balance sheet reserves for the block area are +2.69 million m3, and for the crushed stone area +1.074 million m3. Additionally, there may be an increase in reserves at the bottom of the pit. The initial reserves have been depleted by only ≈ 24% since 1975.

Crushed stone product characteristics: fraction nomenclature according to certificates: 0-5, 5-10, 10-20, 5-20, 20-40, 40-70, mixtures of C-11, C-7, C-5. Compressive strength grade M1200, density 2.7 t/m.cubic meter, radioactivity class I, abrasion grade St.1, impact resistance grade U-75, serial friability g/p = 15%. An operating laboratory with equipment.

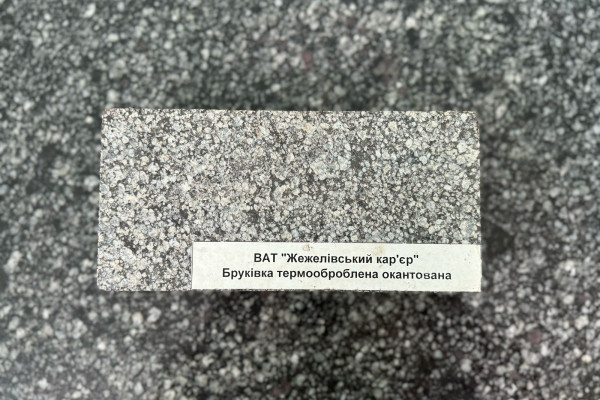

Characteristics of block raw materials: Zhezhelevsky granite has a predominantly dark gray color, medium grain size and is covered with garnet-colored inclusions. The granite has grades M1200 - M1400, radioactivity class one, lends itself well to polishing and is easy to process. Mineral composition: KPS - 20%, Plagioclase - 30-35%, Quartz - 23%, Biotite - 15-25%, others - 2-7%. The main products of the quarry are granite blocks with a volume of up to 4 m3. In addition to blocks, it is possible to produce granite slabs for further processing.

Number of employees: 24 people (engineers - 8 people, other staff - 16 people). Current operation in 1 shift.

Nominal annual capacity of the crushed stone production line = 1,100,000 tons per year

Actual hourly processing capacity = 280-340 tons/hour (depending on the operating mode)

4 crushing stages:

- Receiving hopper (60 cubic meters) with a plate feeder and a SMD-111 jaw crusher;

- Medium-sized cone crusher Metso GP300s + Gyratory CVB 2060 (3 decks);

- Mobile complex with a cone crusher Sandvik СH-440 + Gurkrit (2 decks) + Gurkrit (3 decks);

- Independent line with Metso HP-100 cone crusher + Rumble (3 decks).

A significant modernization of production was carried out in the summer of 2024, the crushing and screening complex was automated on the basis of Skada software with a central control panel, each element of the plant has appropriate indication, protection, and measuring devices to avoid the influence of the human factor, and the line is fully equipped with machinery: two forklifts (CAT, VOLVO), an excavator (Liebherr), two BelAZ trucks (45 tons), two BelAZ trucks (30 tons), KrAZ trucks, three cranes (two KC and RDC cranes), a fuel truck, etc. There is also a tank with a 10 cubic meter license and a garage with repair bays, two Skoda cars.

In addition to the crushing and sorting line, the quarry has a complex of workshops for sawing and polishing slabs from the block quarry, all equipped with crane beams, overhead cranes and hoists.

Also on the territory are the following buildings: operator's room, amenity room, administrative building, checkpoint, warehouse, lathe shop, compressor room, pump room, and garage. The area of all buildings is more than 4000 square meters.

There is a railway loading unit equipped with a ramp with two receiving hoppers and a conveyor loading system for 10-20 receiving cars.

More detailed information is available upon request

Price: USD 3 250 000