The company has been operating since 2016, with a 24/7 work schedule and all permits. Sales of products have been established (more than 40 counterparties).

Location: Kyiv region, Brovary district (40 km from Kyiv).

The flour production complex includes:

- 4 mills P6-AVM-15 in excellent condition, with grain processing from 55 tons per day (or 1800 tons per month), there is a possibility to increase the capacity up to 80 tons per day

- Automated system for receiving and cleaning wheat and feeding it to the mills

- Silos for grain and 4 silos for flour

- Finished goods warehouse up to 200 tons

- Storage bunker for up to 300 tons

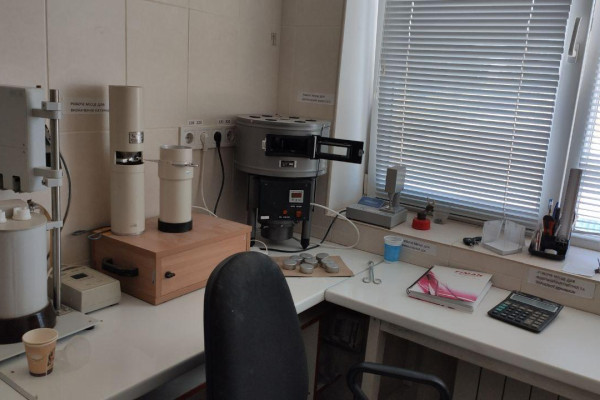

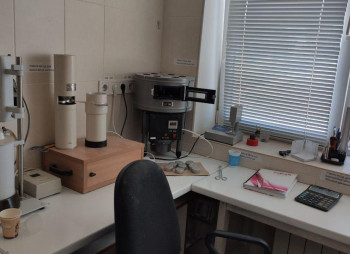

- Modern laboratory for wheat and flour analysis

- Office space of 100 m2 with all amenities

- Kitchen, shower room for staff (30 persons)

- Tool room for maintenance of the complex

- Vehicle fleet, which includes 6 vehicles: Flour truck (shipment without packaging), DAF-105 (grain truck with aluminum trailer), DAF-105 (tilt trailer), DAF-10t, Kara (gasoline) lift up to 2 tons

- Euro containers for staff accommodation for 8 people (shower, kitchen, air conditioning)

- Separate building for paramilitary security (18 video cameras, fire alarm)

Products manufactured:

- Wheat flour in bulk

- Flour 1g

- Flour 2g

- UKTZED for all types of flour 110100

- On bran 230230

Certification: GSTU 46.004-99 Wheat flour. Technical specifications for wheat bran and rye food TU U 10.6-37015101-2017. Capacity registration r-UA-10-19-413.

Technological features of production:

- Grade 1-4 wheat, soft varieties are used

- Flour is usually made from two or three types of wheat. For this purpose, wheat silos are used indoors, and a so-called milling batch is made

- The wheat is fed by a screw to the separator (cleaning), then to the soaking machine and, just before milling, to additional moistening

- We do not use mixtures, there is no need, but we have a new Turkish batcher for this purpose.

- To produce 1 ton of flour, we need 1.36-1.39 tons of grain

- The yield of different flours is on average 72-73%: Bran 25-27, Grain waste up to 1%, Flour 0.2-0.4% (it all depends on the wheat that is purchased)

- All major spare parts and components are available. Repairs are carried out very quickly, replacing one machine takes up to 3 hours, so there are practically no downtimes

- The process from wheat harvesting to flour production is fully automated. We are currently automating the flour injection and loading

- There is no packaging line (there is no need for it)

Key personnel:

- Technologist, 35 years old (higher education in flour milling, grain storage at the elevator, has worked at large and small mills and elevators, is considered one of the best, and is also a manager

- Sales manager (15 years of experience in flour)

- Grain purchasing manager (30 years of experience)

- Head of the laboratory (responsible for flour quality, a 35-year-old woman with a university degree in the specialty - also one of the best)

- 2 laboratory assistants with extensive experience

Productivity and economic potential:

- The maximum productivity per month is 1800 tons (currently operating at 60-70% of capacity).

- Electricity costs per ton of processed products for the entire complex average up to 60 kWh/t.

- The average profitability at 100% utilization is 20-23%.

- The accounts receivable repayment period is 45-60 days, so there is a need for working capital at 100% utilization of about $1 million (to purchase wheat at current prices, pay taxes, electricity, salaries, etc.)

Land area: 1 hectare in private ownership (0.5 hectares are free for expansion of the complex, in particular, construction of an elevator / grain storage warehouses).

Utilities:

- Electricity: 200 KW (2 inputs)

- Well (borehole)+documents

- Septic tank

- To the railway line 10 km

Offer for investors:

- Sale price: $850,000

- There are 2 options for sale: LLC or the complex separately.

- Reason for sale: lack of working capital