Location: Chernihiv Region, Kulykivka District, Horbove village (30 km from Chernihiv).

The complex is located in close proximity to a regional highway. The distance to the nearest railway line is 5 km, with a potential to construct a railway siding.

Characteristics of the Property Complex

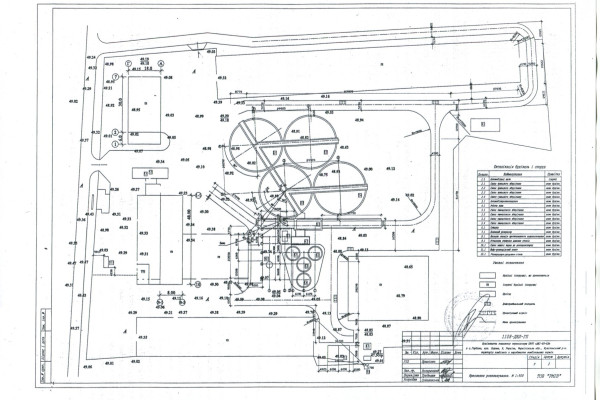

The complex is situated on a land plot of 3.5174 hectares. The land plot is under long-term lease for a period of 15 years.

The production complex includes the following facilities: two production buildings (total area: 3,200 sq.m), administrative building, transformer substation, checkpoint, truck scales, laboratory, water well, water tower, two pumping stations, fire reservoir, warehouses for floor grain storage (capacity of 14,000 tons), grain storage silos (capacity of 6,000 tons), and a finished goods warehouse (capacity of 3,500 tons).

Total building area: 11,282 sq.m.

All production premises are in satisfactory condition. In recent years, the checkpoint, laboratory, grain warehouses, truck scales, pumping station, and administrative building have been renovated; a new pumping station was built; the main building was reconstructed; a production building with bulk grain storage tanks was established; external water supply, sewage, and filtration fields were installed.

The property complex of the plant is equipped with essential utilities: electricity supply of 600 kW (the transformer substation is located 30 meters from the plant, with an additional available capacity of 1,500 kW), a water well, a water supply system across the territory, a fire water supply system across the territory, a fire reservoir, an external sewage system, filtration fields, heating of the administrative complex and the flour mill.

Gas has been supplied to the territory of the complex; the project also plans to connect gas to the grain dryer and the administrative and utility complex.

The access roads and internal territory are asphalted, and the complex is fenced with a reinforced concrete fence.

There is sufficient free space on the territory for the construction of new real estate facilities.

Characteristics of the Flour Mill

The flour mill was built in 2021 and commissioned in January 2022 but has not operated due to the outbreak of the war.

The mill is designed for 75% extraction wheat flour milling with a capacity of 130 tons per day.

The technological line includes: full automation of the production process, automation of the grain moistening process, flour drying in an aerosol transport system, bulk loading of flour into flour trucks.

The flexible technological scheme allows two-grade milling with the following output: top-grade flour – 54%. first-grade flour – 10%,semolina – 10%, bran – 25% and capability for flour fortification.

Additional Characteristics of the Grain and Feed Mill Complex

- Full automation of technological processes (software: "Unity Pro" for lower-level control and "Citect" SCADA system for operator workstations — both by Schneider Electric);

- Automation of the grain moistening process;

- Flexible technological scheme allowing the production of up to 10% semolina;

- Ability to produce flour suitable for pasta from highly vitreous wheat;

- Capability for flour fortification (adding dry gluten, micronutrients, and vitamins);

- Development of technical specifications for fortified flour (allowing participation in UN flour supply tenders);

- Flour drying in the aerosol transport system;

- Bulk loading of flour into flour trucks;

- Developed projects for mill and groats plant recirculation;

- Project documentation for a feed mixtures workshop based on grain cleaning and processing by-products (wheat, corn, and peas);

- Developed feed mixture recipes based on mill and groats plant by-products;

- Exploration of new directions in food industry technologies, with prospects for establishing high-quality instant food production using free warehouse areas.

Project for Additional Elevator Construction — KMZ Industry, 27,500 Tons Storage Capacity

The construction of a grain storage complex is part of the plant’s reconstruction plan.

Project documentation has been developed for the construction of a grain storage facility by KMZ Industry with a total storage capacity of up to 24,000 tons, including a grain cleaning and drying system.

The grain warehouse complex with cleaning, drying, transportation, and loading systems will be located on the free territory of the plant.

The elevator complex will include equipment by KMZ Industry (Karlivka, Poltava Region):

- 4 grain storage silos (5972 tons each for wheat);

- 7 silos for non-standard grain with conical bottom (505 tons each);

- 1 small conical silo (47 tons);

- Grain dryer;

- Two drum separators for grain cleaning;

- Transporters, conveyors, bucket elevators, and loading equipment.

Equipment Productivity and Characteristics:

- Total elevator capacity: 23,388 tons (wheat basis);

- Grain dryer capacity: 50 tons per hour (wheat);

- Natural gas consumption during autumn grain drying: 458 nm³/hour.

- The operation of the grain storage complex will be highly automated, and its operation will be maintained by 10 employees; during peak load periods in the 3rd and 4th quarters, grain reception and drying will be carried out around the clock, and 22 employees will work at the grain storage facilities. Operational costs for maintaining the complex during the winter-spring period will be minimal.

Investor Offer:

- Sale Price: $2,600,000

- Subject of Sale: Property complex (real estate objects, production lines, and equipment)

- Reason for Sale: Lack of working capital for further project implementation