In Zhitomir, starting in 2024, a new waste processing plant, built and equipped with investments from a private investor, began operating in experimental mode. At the enterprise, the waste received is already cleaned, sorted and processed into biofuel, and by the end of 2024 they plan to expand production capacity.

Production of alternative fuel is planned at 30 thousand tons. As of today, the plant processes up to 15 tons of waste every hour. Biofuel, as a cheap alternative to coal and gas, is the final product of production, which is already purchased by Ivano-Frankivsk, Kamenets-Podilsky and Zdolbunovsky cement plants.

Compost was planned to be one of the types of products for commercial sale, but it is not of adequate quality. Now we are looking for an alternative solution to replace it, and what will be produced additionally.

“Purchase prices vary depending on logistics, but today the range ranges from 4000-4300 hryvnia with delivery and VAT per ton,” said Evgeniy Barakh, managing partner of TS Social Project LLC.

According to the manager, only 12 million euros of investment were invested in the construction and equipment of the enterprise in Zhitomir.

“The plant is still operating in test mode. Throughout 2023, we were engaged in commissioning and certification of products. Such an enterprise as in Zhitomir currently has no analogues in Ukraine. And the preparatory processes continued for a long time, because there was no money for these products state standards of Ukraine (DSTU), no certificates of conformity, no proper conclusions of environmental, sanitary, epidemiological services. We, in fact, did all this from scratch,” said the managing partner of TS Social Project LLC.

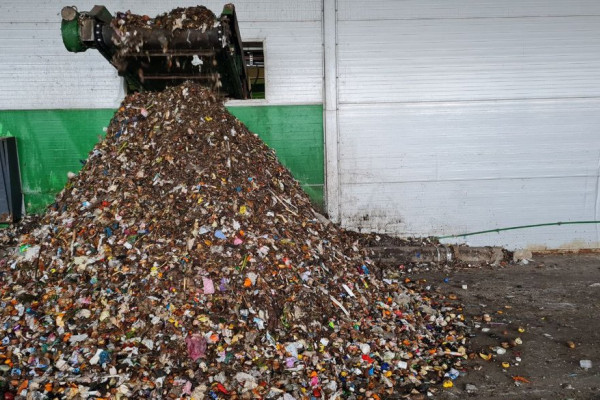

According to him, mixed waste is poured out and, with the help of a loader, tipped into a bunker, and from there to a sorting line, where it is separated into organics and solid household waste that are not suitable for use, and then for cleaning and recycling. As a result, only selected secondary raw materials are processed.

"On the sorting line for subsequent processing, 10 types of high-quality secondary raw materials are sorted, which are processed. We separate three types of PET bottles (three colors), sort three types of broken glass, separately high-pressure polyethylene films and stretch films, aluminum cans, two types: mixed and pure polypropylene,” said Yuri Panasyuk.

In a rotary drum, organic matter and small low-quality waste are sorted separately. Sorting center workers, of whom there are 30 on staff, are involved in sorting selected recyclables.

“I sort bottles - separately from household chemicals, separately from aluminum. I used to sort paper, but later this work was canceled,” said employee Olga.

Another worker, Yulia, said that when sorting garbage, she more than once found dead dogs and cats weighing 20 and 40 kilograms, as well as pigs’ heads and the remains of other animals. Such waste is sent for recycling, that is, it is burned.

Alexander also works at the company. It selects garbage at the first stage, when it is still mixed. He says the range of waste varies.

“As a rule, there are a lot of bags here. You have to tear them apart, pick out waste from there, take out pieces, rags, stones. There are also a lot of iron objects,” said Alexander, a waste plant worker.

According to the chief engineer of the enterprise, Pavel Furman, one technological line of joint Croatian-Ukrainian production is currently operating for waste processing. By the end of the year, the company plans to install plastic and wood processing lines.

"We plan to install more auxiliary lines, we plan to modernize the enterprise. Because these production capacities of the Croatian lines that we currently have are not enough to process all the waste of the city of Zhitomir. We will improve. Over the next two months we will supply auxiliary equipment, and then we will be able to process up to 20-22 tons per hour,” said Pavel Furman.

Project implementation stages

According to the plan, by the beginning of 2022, in Zhitomir, on the outskirts of the city, they planned to build the first waste recycling plant in Ukraine for investor money with a capacity of 85 thousand tons per year. The project cost of construction of the plant was 9 million euros. It was stated that the initial capacity would be 85 thousand tons of waste processing per year. However, due to the plant’s capacity, it turned out to be no more than 40-45 thousand tons annually, that is, half as much. One of the main reasons is that the equipment is not adapted to the modern realities of Ukraine. The second reason is the culture of waste management in our city and in Ukraine as a whole.

In April 2021, the investor announced that construction of a waste recycling plant in Zhitomir would begin in May.

On September 20, 2021, a symbolic capsule was laid into the already built foundation of one of the workshops of the future waste processing plant.

At the beginning of February 2022, the installation of equipment at the waste processing plant was completed; the first industrial batch of waste was planned to be received in February-March 2022, but a full-scale war with Russia prevented it.

On February 23, 2023, during the consideration of the issue of operating the city solid waste landfill at a session of the Zhytomyr City Council, Zhitomir mayor Sergei Sukhomlin said that the first stage of a waste recycling plant was launched in Zhitomir.

Today, the owners have decided that without additional financial investments and without reconstructing the line for sorting and producing alternative fuels, they will not achieve the results they planned. Therefore, the plant owners decided to look for technical solutions to optimize production processes. Today this work has already been done, now we are looking for credit opportunities in order to receive a loan to purchase equipment and install it. Already in August-September 2024, this equipment should operate at full capacity in accordance with the indicators stated at the beginning.